WARNING: Working with electricity is dangerous. This article will teach you several ways to convert a refrigerator into a chamber for curing meat or for aging cheese. (The same principles can be used to convert a refrigerator into a lagering chamber for making homebrew lager beer, or converting a chest freezer into a kegerator.) If you choose the route that requires wiring, I cannot be held responsible for any damage to life or property should your wiring fail. If in doubt, consult an electrician, and always obey local, state, and federal electrical codes when modifying the electrical connection for appliances.

Folks with a basement or cellar anywhere in the US (or most temperate climates) generally have the proper temperature and humidity range to cure meat simply by hanging properly salted meat in that basement or cellar. (Though insects, mice, and wild molds can be a problem.) The finest meats in the world are cured in centuries-old basements in Europe. But for those of us without basements or cellars, curing our own meat requires a curing chamber that provides the ideal temperature and humidity range.

It’s fairly simple to convert an old refrigerator into such a chamber. I got an old fridge on Craigslist for $50, but you can often find them in the free section if you’ll be patient and quick to respond once they are listed. (If you transport a fridge on its side, rather than upright, you need to leave the fridge sitting upright, unplugged, for a couple of days, to let the coolant settle properly.)

The first object is to rig a rack system near the top of the fridge chamber, on which the meat will hang. If you ever plan on curing whole hams, this rack may need to support fairly heavy weights (25-30 pounds per ham for a large one.) If you’re just curing sausages, it may not need to be as strong. If the fridge has wire racks, you may be able to just move the racks to the top of the fridge and hang the meat directly from the racks. My fridge came with glass shelves, so I removed all the shelves. I made my rack system out of aluminum from Home Depot. I bought square tubes which anchor the racks on each end, and used an angle grinder to cut slots in the square tube so I can customize the distance between the racks:

I used a fast-setting epoxy to glue the square tubes to the walls of the fridge. (Make sure they are level and even with each other!) Then I just slid the bars into the slots, and placed some S-hooks over the bars to hang the meat. This type of rack is sturdy enough to cure full-sized hams.

Wood may be easier to work with, but the conditions inside the curing chamber will be damp (around 65% humidity) which provides a perfect place for mold to grow, so I encourage you to avoid wood, if possible. Get creative!

Once you have your fridge and rack system set up, you need 5 electronic components to convert the fridge into a curing chamber:

- An external temperature controller/thermostat

- An external humidity controller

- A cool-mist/ultrasonic humidifier

- A thermo-hygrometer (weather station)

- A fan

The first two items are available on the internet in a wide range of prices, depending on how convenient you want the conversion to be. The simplest units are plug-and-play. You plug the controllers into any outlet. You plug the fridge into the temperature controller and you plug the humidifier into the humidity controller. You set the proper temperature and humidity ranges, you place the sensor probes into the fridge chamber, and you’re good to go. Unfortunately, these units are the most expensive. The plug-and-play temperature controllers range between $50 and $80, like this one on Amazon. The humidity controllers range between $50 and $100, like this one or this one. If you’re not accustomed to electrical work, I strongly encourage you to spend the extra money and get one of these.

For those of you who are handy, there are some cheaper units now available that were designed for controlling temp and humidity in computer server racks, but they are bare-bones units and you’ll have to provide power (via a cord, or wiring them to an outlet), and make your own connections to the fridge and humidifier (either by direct wiring or hard-wire, or by wiring the controllers to outlets.) The STC-1000 unit for controlling temperature costs about $25. (Be cautious if you find it cheaper. Cheaper units may ship from China and take weeks, and be certain you order the proper voltage for your country…in the US this is 110 volts.) The WH8040 unit for controlling humidity costs around $35. (Similar warnings for this unit, too.)

I’m going to explain how to hard-wire your fridge and humidifier directly to these units, because there are other articles out there on how to wire outlets to the units, and then plug in your fridge and humidifier. That’s extra cost, to me, and requires that I construct a housing to hold the units and the outlets. And I’m looking for the quickest route to efficiency. Please note that local electrical codes may not like you to have exposed wiring connections.

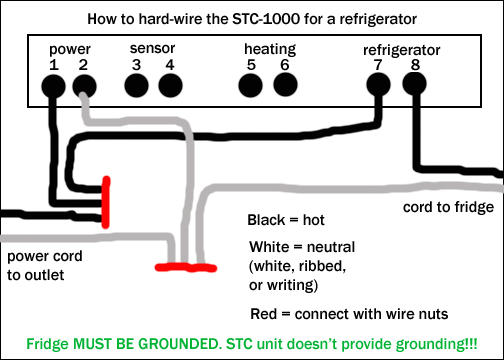

Let’s start with the STC-1000 to control the temperature of the fridge:

The unit comes with wiring instructions translated from Chinese, and they’re completely useless. So I’ve made a wiring diagram:

You will need to buy or re-purpose a power cord to power the unit. The cord needs to be able to handle enough current to power the fridge, so don’t use a lamp cord! If you use a grounded power cord, you can connect the fridge’s green grounding wire to the green wire of the power cord. (If you use a 2-wire power cord, you will need to connect the green wire inside the fridge’s cord to the grounding screw on an outlet, or follow the alternate grounding procedure later in this post.) Using a grounded power cord is preferable. You will need to cut the plug off the refrigerator’s power cord and strip off the insulation from the hot, neutral, and ground wires.

Some basic electrical knowledge here for those of you who are unfamiliar. A typical power cord contains a hot wire that carries the current to the device…a neutral wire that returns the current to the outlet, thus completing the circuit…and a ground wire that carries away dangerous electricity if there is a wiring failure inside the device, so that you don’t get shocked when you touch it.

The hot wire is always black. The neutral wire is usually white…but if there’s no white wire, the neutral wire will be indicated by writing, markings, or ribbing along the cord’s insulation, so look or feel closely to determine which wire is the neutral wire. The ground wire is either bare copper or green.

So the hot wire from your power cord needs to be spliced to two other short bits of black wire (called “pigtails”) that run to slots 1 and 7 on the STC-1000 unit. Tape these wires together with electrical tape, and connect them securely with a properly-sized wire nut. The neutral wire from your power cord needs to be spliced to a pigtail that runs to slot 2, and to the neutral wire on the fridge’s power cord. The hot wire on the fridge power cord needs to run to slot 8 on the unit. (The neutral wire on the fridge power cord has already been connected to the neutral wire from the main power cord, along with a pigtail to slot 2.)

When you get done, it’ll look kinda like this:

(You shouldn’t need a heater unit unless your curing fridge sits outside in a very cold climate, but if you do, a heating pad will generally work nicely. To add a heater to the system, run a pigtail from the black power cord bundle to slot 5. Run the heater’s hot wire to slot 6. Connect the heater’s neutral wire to the neutral bundle.)

The fridge MUST be grounded, or you risk electrocuting yourself when you touch the fridge if the wiring inside the fridge fails. The grounding wire from the fridge can connect directly to the green or bare copper wire inside the power cord, if it’s a 3-prong cord. If you’ve used a 2 prong power cord, like I did, you need to connect the fridge’s ground wire to the grounding screw inside a nearby electrical outlet, or you can take a regular 3-prong plug, remove the hot and neutral prongs, leaving just the grounding prong, and connect the ground wire to that prong:

Now you need to plug in the power cord to an outlet. (I bought a special extension cord that has 4 outlets on the end that will sit next to the fridge. 4 items will need to be plugged into the outlet. You can also use a regular extension cord and a power strip.) The STC-1000 unit will power up, and now you need to set it.

The following paragraph details instructions for setting the STC-1000, you can skip this unless you are actively setting the device right now: Press and hold the S key for 3 seconds to enter the setting mode. The first item that displays is F1, which is the temperature setting. The unit is in Celsius, so you’ll have to do a quick conversion. I keep my curing chamber in the low 60s Fahrenheit, so 18C is the corresponding setting. To set the temp, press and hold the S key while pressing the up or down arrow until you reach the temperature that you want your curing chamber to remain. Then press the power button once quickly to save the setting. (The setting will remain even if your power goes out…it only resets to the default setting if you manually reset the device.) The other settings don’t need to be modified unless you have problems later. (F2 is the “Difference value” which tells the fridge when to turn on after the temperature rises a specific number of degrees above your setting. The default setting is half a degree Celsius, which is fine as it is. F3 is the “Compressor delay time” which gives the fridge’s compressor a result, because you don’t want it cycling on and off every 30 seconds. The default setting is 3 minutes, which is fine. F4 is the “Temperature calibration value” which is used if you discover your device isn’t accurate and you need to adjust it. To switch between these values in the setting mode, press the S key multiple times until you arrive at the feature you need to change. If, at any time during the setting process, you don’t press a key for 10 seconds, the device forgets what you’ve done and returns to its operation mode. Don’t forget to press the power button once quickly to save your settings.)

Make sure to attach the temperature probe to slots 3 and 4 on the unit. Then run the sensor probe into your fridge and make sure it’s not touching the walls, the racks, or the meat. Now the STC-1000 unit will keep your fridge in the low 60s…the perfect temp for curing meat.

Now we need to address humidity. Normal refrigerators run very dry, so you’ll need to add moisture to the chamber to keep it in the low 60% range. We do this with a cool-mist humidifier, also called an ultrasonic humidifier. (DON’T use a conventional vaporizer, which uses warm heat to evaporate the water. This will raise the temp inside the chamber each time the unit comes on.) Get yourself the largest-capacity humidifier you can afford, so you don’t have to refill the unit every few days. The unit I’m using holds about 1 gallon of water. It cost me $30 on Amazon and was fairly well reviewed. (There is also a pig-shaped humidifier on Amazon, which is supremely appropriate, but the reviews aren’t as good.)

Place the humidifier in the bottom of the fridge and run the wire out the side of the door. Cut the plug off the end of your humidifier and strip the insulation off the cords. (Humidifiers don’t usually have a ground wire, just a hot and a neutral.)

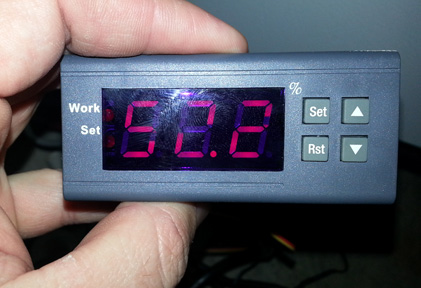

Now we get out our WH8040 humidity controller:

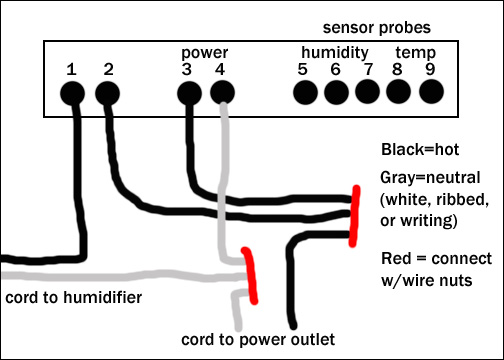

We wire the humidifier to the unit using the following diagram:

The hot wire from the power cord connects to two pigtails, which are connected to slots 2 and 3 on the WH8040. The neutral wire from the power cord connects to a pigtail to slot 4, as well as the neutral wire from the humidifier’s power cord. And the hot wire from the humidifier connects to slot 1. The WH8040 has 2 probes that it uses to calculate humidity…a temp probe which connects to slots 8 and 9, and a vapor probe that connects to slots 5, 6, and 7. Run the probes into the refrigerator’s chamber, and like the temp probe, they should hang freely in the area where the meat does.

When you get done wiring it, the unit will look sorta like this:

The following paragraph details instructions for setting the WH8040, you can skip this unless you are actively setting the device right now: Press and hold the SET key for 3 seconds to enter the setting mode. The first value is HC, which tells the unit whether to dehumidify, or humidify. Press the SET key again, and use the up or down arrows to set this value to H (humidify). Then press the SET key again to save the value and return to SET mode. Press the UP key to move to the next value, D, which is “Hysteresis.” Leave this at its default setting. Press the UP key again to move to the next value, LS, which is the lowest humidity range you want to keep. Press the SET button and adjust this setting to 55%, or whatever the lowest humidity is acceptable for you. Then press the SET button again. Use the UP arrow to move to the next value, HS, which is the maximum humidity. Click SET and use the arrows to set this limit to 65%. The remaining settings can be left at their defaults unless you need to modify them later. CA is humidity calibration…if your unit isn’t measuring the humidity correctly, you can override the settings by plus or minus 5%. PT is the delay time between turning your humidifier on and off, and the default is set at 1 minute. Press the RST key to leave the set mode.

Now you can mount your WH8040 to the side of your fridge with double sided tape or velcro.

Again, if all that wiring sounds too complex for you, you can simply buy a plug-and-play temp controller and humidity controller, you’re just gonna spend an extra $75-$100. Do that, and your system will be set up in 15 minutes.

Now it’s time to place the fan in the bottom of the fridge next to your humidifier. I got a small metal desk fan on Amazon for $13 that was well reviewed. The air inside the curing chamber needs to circulate constantly to help dry the meat, so just run this cord out the back of the door and plug it into your power supply.

The final step is to install your thermo-hygrometer, which keeps track of the temp and humidity inside the chamber, so you know if your controllers are working properly. I got mine on Amazon for $18. It has a wireless remote unit that I velcroed to the inside of the fridge. It is battery powered, and sends the information to the main unit, which I velcroed to the fridge door.

Now the curing chamber is complete! Give it a few hours to operate before you start tweaking. Remember that your fridge will probably have its own settings for temperature, which can affect the whole system. (I have mine set for the warmest temp.) Here’s what the final setup looks like on the inside (completely with wild boar already curing):

Note the sensors all hanging on the center and upper left side of the pic.

The freezer above is now empty space. And in MY converted fridge, the freezer maintains a temp of about 50 degrees, when the main chamber is 65. 50F is the PERFECT temp for aging cheese! So I can age cheese AND cure meat in the same unit. Don’t ever try to age cheese in the SAME chamber as curing your meat. The bacteria that you inoculate cheese with (especially bleu cheeses) isn’t what you want growing on your meat. So they need to be separated.

All-in-all, this setup cost me about $200. Not cheap by any means. But if you’re serious about making your own charcuterie and salumi at home, this is money well invested. (A single Iberico ham or Prosciutto di Parma can set you back up to $1000!) Some people have luck using a small college dormitory fridge, moved to the warmest setting, with a dish of water in the bottom to boost humidity. This is way cheaper and easier to set up…but you lose control over your environment, which will yield unexpected results. And if you’re going to great lengths to source quality meat, you don’t want it rotting away in your garage.

Now you’re ready to make prosciutto, coppa, spalla, guanciale, salami, and age your own hams. Of course, that’s an entirely separate blog entry. Check this out for starters!

A video will be posted soon, which may help those who are more auditory and visual.

Please feel free to comment below, especially if you already cure your own meat at home, if you have a different setup, or if you make this setup and try it. And subscribe to my blog in the upper right corner of this page below the header image so you don’t miss out on other great posts!

Leave a Reply

You must be logged in to post a comment.